To optimize the selection of a vibration isolator one should consider:

- device’s full mass

- amount of points of support

- load concentration on a point of support

- rotational speed of spinning/rotating elements

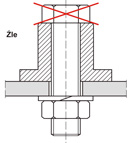

- fixing method to a mounted device

Collapsible spring vibration isolators selection and construction data tables.

| Type of vibration isolator | |||||

|---|---|---|---|---|---|

| SSA | SSB | SSC | |||

|

|

|

|||

|

Size of a vibration isolator |

Spring stiffness [kg/mm] |

Maximum load |

Minimum natural frequency [Hz] |

Minimum percentile effectiveness of vibration isolation at a specified driving frequency in [Hz] or [rpm] | ||||

|---|---|---|---|---|---|---|---|---|

| axial load [kg] | axial deflection[mm] | 50 Hz 3000rpm | 25 Hz 1500rpm | 16,6 Hz 1000rpm | 12,5 Hz 750rpm | |||

| 1 A | 0,76 | 38 | 50 | 2,25 | 99 | 99 | 98 | 96 |

| 1 B | 1,22 | 48 | 40 | 2,54 | 99 | 98 | 97 | 95 |

| 1 C | 2,01 | 76 | 38 | 2,59 | 99 | 98 | 97 | 95 |

| 1 D | 4,50 | 135 | 30 | 2,91 | 99 | 98 | 96 | 94 |

| 1 E | 6,18 | 154 | 25 | 3,19 | 99 | 98 | 96 | 93 |

| 2 A | 1,23 | 61 | 50 | 2,26 | 99 | 99 | 98 | 96 |

| 2 B | 2,15 | 86 | 40 | 2,52 | 99 | 98 | 97 | 95 |

| 2 C | 3,36 | 127 | 38 | 2,59 | 99 | 98 | 97 | 95 |

| 2 D | 7,44 | 223 | 30 | 2,91 | 99 | 98 | 96 | 94 |

| 2 E | 9,82 | 245 | 25 | 3,19 | 99 | 98 | 96 | 93 |

| 3 A | 1,61 | 80 | 50 | 2,26 | 99 | 99 | 98 | 96 |

| 3 B | 3,26 | 130 | 40 | 2,52 | 99 | 98 | 97 | 95 |

| 3 C | 5,99 | 227 | 38 | 2,59 | 99 | 98 | 97 | 95 |

| 3 D | 12,44 | 373 | 30 | 2,91 | 99 | 98 | 96 | 94 |

| 3 E | 15,81 | 395 | 25 | 3,18 | 99 | 98 | 96 | 93 |

| 4 A | 2,49 | 124 | 50 | 2,26 | 99 | 99 | 98 | 96 |

| 4 B | 4,38 | 175 | 40 | 2,52 | 99 | 98 | 97 | 95 |

| 4 C | 8,26 | 313 | 38 | 2,57 | 99 | 98 | 97 | 95 |

| 4 D | 16,62 | 498 | 30 | 2,91 | 99 | 98 | 96 | 94 |

| 4 E | 28,66 | 716 | 25 | 3,18 | 99 | 98 | 96 | 93 |

| 5 A | 5,02 | 251 | 50 | 2,25 | 99 | 99 | 98 | 96 |

| 5 B | 9,58 | 383 | 40 | 2,52 | 99 | 98 | 97 | 95 |

| 5 C | 12,13 | 460 | 38 | 2,58 | 99 | 98 | 97 | 95 |

| 5 D | 24,99 | 749 | 30 | 2,91 | 99 | 98 | 96 | 94 |

| 5 E | 41,31 | 1032 | 25 | 3,18 | 99 | 98 | 96 | 93 |

| 6 A | 13,36 | 534 | 40 | 2,52 | 99 | 98 | 97 | 95 |

| 6 B | 22,54 | 856 | 38 | 2,58 | 99 | 98 | 97 | 95 |

| 6 C | 44,26 | 1327 | 30 | 2,91 | 99 | 98 | 96 | 94 |

| 6 D | 66,91 | 1672 | 25 | 3,18 | 99 | 98 | 96 | 93 |

|

Size of a vibration isolator |

Mass 1 pc. [kg] |

Dimensions [mm] | Fixing method | ||

|---|---|---|---|---|---|

|

D |

H* |

Bushing** | Socket | ||

| MxL [mm] | Mxg [mm] | ||||

| 1 A,B,C,D,E | 0,2 | 20 | 108 | M8 x 30 | M8 x 28 |

| 2 A,B,C,D,E | 0,3 | 25 | 110 | M10 x 30 | M10 x 29 |

| 3 A,B,C,D,E | 0,4 | 32 | 110 | M12 x 50 | M12 x 29 |

| 4 A,B,C,D,E | 0,6 | 40 | 112 | M16 x 50 | M16 x 30 |

| 5 A,B,C,D,E | 0,9 | 50 | 112 | M16 x 50 | M16 x 30 |

| 6 A,B | 1,5 | 63 | 112 | M16 x 50 | M16 x 35 |

| 6 C,D | 1,9 | 63 | 118 | M20 x 50 | M20 x 40 |

** possibility of manufacturing a screw with a different thread M and length L.

Vibration isolator’s marking:

Collapsible spring vibration isolator SSA, SSB or SSX

SSA, SSB, SSC – X – type

X – size (1A – 6D)

Exemplary order:

Collapsible spring vibration isolator

SSB – 3A pcs

SSC – 6D pcs.