To optimize the selection of a vibration isolator one should consider:

- device’s full mass

- amount of points of support

- load concentration on a point of support

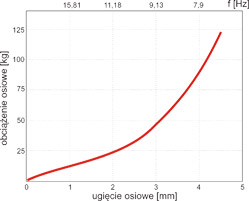

- rotational speed of spinning/rotating elements

Bowl vibration isolators selection and construction data tables.

|

| Type and size | Axial load range[kg] | Dimensions [mm] | Mass 1 pc. [kg] | |||

|---|---|---|---|---|---|---|

| D | H | M | h* | |||

| WM – 4 | 10 – 60 | 42 | 77 | M10 | 26 | 0,15 |

| WM – 8 | 60 – 200 | 82 | 100 | M12 | 34 | 0,40 |

| WM – 12 | 200 – 500 | 122 | 133 | M16 | 41 | 1,20 |

** possibility of manufacturing a screw with a different thread M and length L.

Vibration isolator’s marking:

Bowl vibration isolator X-Y

X– type (4-12)

Y – vibration isolator’s size (4-12)

Exemplary order:

Bowl vibration isolator WM – 4 pcs.